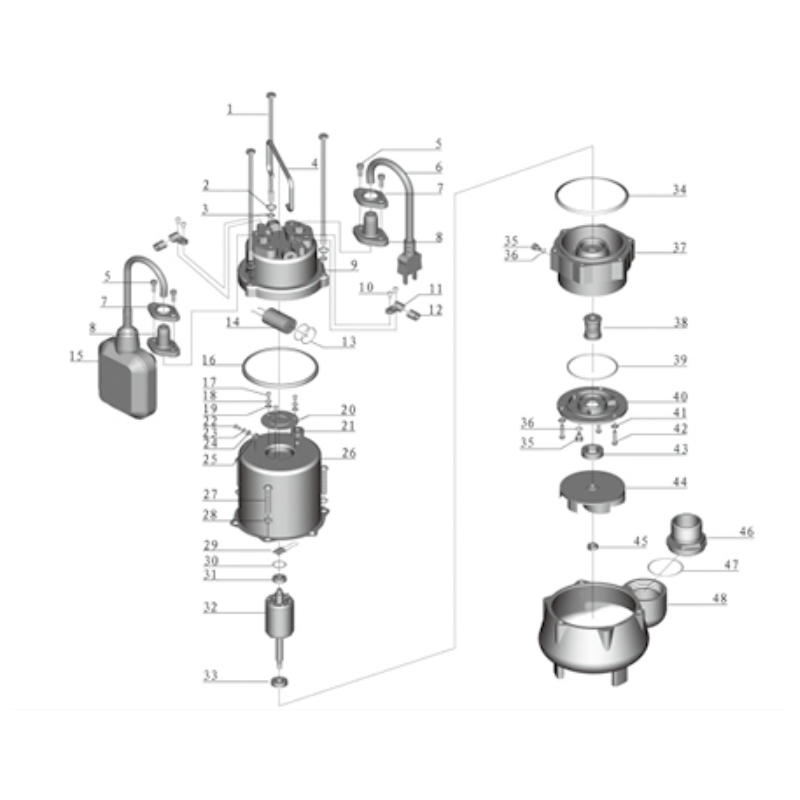

| No. | DESCRIPTION | MATERLAL | NO. | DESCRIPTION | MATERIAIL | |

| 1 | Bolt | 11 | 25 | Nut | 11 | |

| 2 | Stretching washer | 11 | 26 | Motor stator | 11 | |

| 3 | Washer | 11 | 27 | Screw | 11 | |

| 4 | Handle | 11 | 28 | Stretching washer | 11 | |

| 5 | Screw | 11 | 29 | Thermal protector | ||

| 6 | Cable | 30 | Undulated washer | 1586 | ||

| 7 | Flange | 11 | 31 | Ball bearing | ||

| 8 | Cable protector | cR | 32 | Rotor | ||

| g | apacitor cover | No35B | 33 | Ball bearing | ||

| 10 | Screw | 11 | 34 | Rubber washer | NBR | |

| 11 | Cable presser | 11 | 35 | Screw | 11 | |

| 12 | Protector | NR | 36 | Oring | NBR | |

| 13 | o"ring | NBR | 37 | onnection part | No35B | |

| 1i | Capacitor | 38 | Mechanlical seal | Aumina Graphite | ||

| 15 | Float switch | 39 | Oring | NBR | ||

| 16 | Rubber washer | NBR | 40 | Oil chamber cover | No35B | |

| 17 | Screw | Fe360A | 41 | Washer | 11 | |

| 18 | Strotching washer | 1566 | 42 | Screw | 11 | |

| 19 | Washer | Fo360A | 43 | Oil scal | ||

| 20 | Press plate | Fe360A | 44 | lmpeller | PA66730%Flber | |

| 21 | Line protector | NBR | 45 | Nut | 11 | |

| 22 | Screw | CuZn40 | 46 | Out-let connec!or | ABS | |

| 23 | Stretching washer | 1566 | 47 | -oring | NBR | |

| 24 | Washer | CuZn40 | 48 | Pump body | No35B |

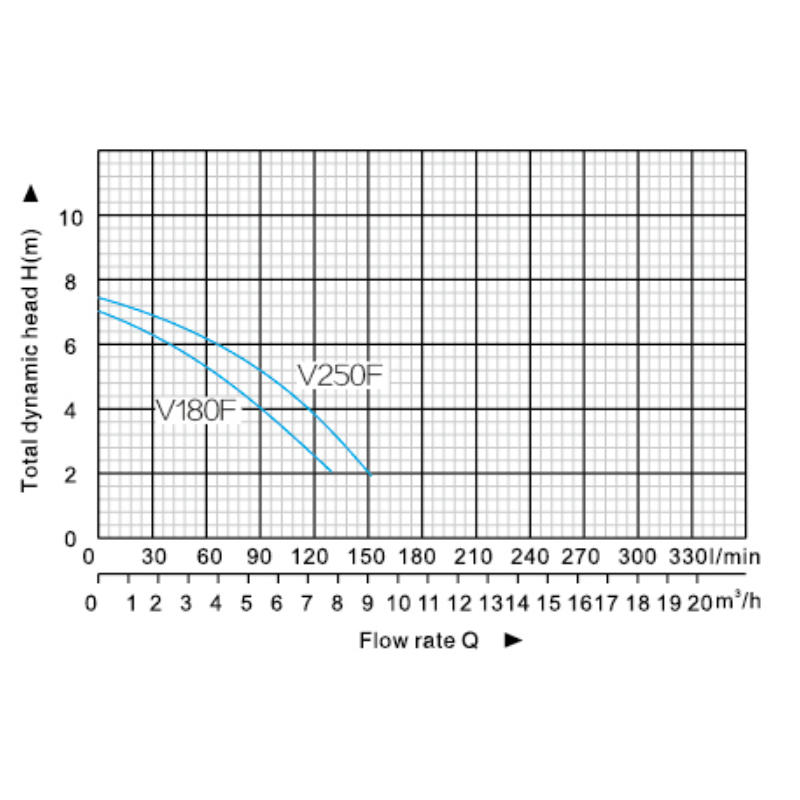

| Model | Power | Outlet Diameter |

Voltage Frequency |

Max. Flow |

Max. Head |

Max. Diameter |

G.w. | Packing |

| (KW) | (mm) | (VIHz) | (L/min) | (m) | (m) | (kg) | (cm) | |

| V180F | 0.18 | 40 3225 | 220/50 | 133 | 7 | 15 | 8.5 | 20.0X19.0X40.0 |

| V250F | 0.25 | 4032 25 | 220/50 | 150 | 7.5 | 15 | 9.5 | 20.0X19.0X40.0 |

V(WQ)submersible sewage pump series, a branch of single-phase and three-phree- phase drainage pumps,will be your ideal drainage helper. It can work safely and efficiently at high flux with the feature of complete heads.The design is designed to a wide tunnel which helps to convey the long fiber liquid or the solid whose diameter is aboit 15 -25mm.

V(WQ) sewage pump series, a branch of single-phase and three-phree- phase drainage pumps, is your ideal drainage helper. The letter "V" which substitutes for the letters "WQ" indicates the distince design of the filter and the broadness of the high efficient area. It can work safely and efficiently at high flux with the feature of complete heads. The design is designed to a wide tunnel which helps to convey microparticles or solids whose diameter is 15-25mm. The selection of bottom suction structure, stainless steel and special cast iron made it has capabilities of complete drain and high resistance of abrasion and corrosion

The V(WQ) sewage pump is a single-phase and three-phase drainage pump which makes it suitable for many types of drainage tasks. It features a wide high efficient area filter and has a stainless steel cast that prevents corrosions, making it especially useful for long term use.

V-WQ Sewage Pump is used for the sewage and pump station of municipal or rural sewers. It pumps the water to a higher level after treatment and the rest of the liquid gas is discharged into the river or ocean.

They can operate safely and efficiently at high flux with the feature of complete heads.The design is designed to a wide tunnel which helps to convey the long fiber liquid or the solid whose diameter is aboit 15 -25mm.They are completely made of stainless steel, special cast iron which makes them have the capabilities of complete drain and high resistance of abrasion and corrosion.

This sewage pump has excellent performances in terms of capability, economy, noise reduction, etc.. Because its normal position is under water, however it can endure at least 10 years without any maintenance at all even if the use condition is harsh.

The pump will be your ideal drainage helper. With its special design, the pump has the capabilities of complete drain and high resistance of abrasion and corrosion

Bottom Suction: V(WQ) Sewage Pump is ideal for the drainage of chemical industry and chemical plants, agricultural and industrial wastewater treatment, hospital waste water treatment and other projects with a strict requirement on biodegradation. It has high efficiency at low speed and high flow rate, low power consumption, small noise while working, long service life, reliable performance and strong adaptability to work environment.

English

English

Español

Español

عربى

عربى